PRODUCTION PROCESS

PRODUCTION PROCESS

PRODUCTION PROCESS

Our commitment to making quality steel products means we closely monitor every stage in the production process, applying the best practices and continous improvement.

1

Steel Scrap

2

Induction Furnace

3

Chemical Composition Check

4

Continous Casting Machine

5

Reheating Furnace

6

Rolling Mill

7

Cooling Bed

8

Visual & Mechanical Test

9

Packing & Delivery

STEEL MAKING

INDUCTION FURNACE

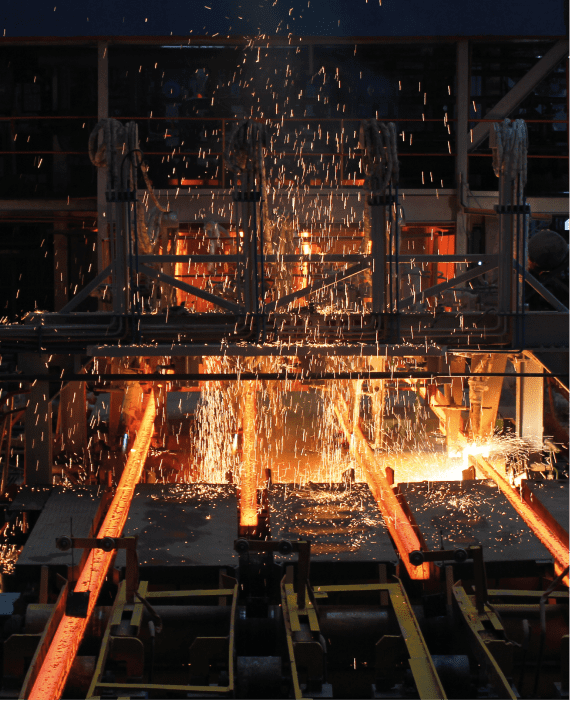

Continuous Casting Machine

By Shengli Intelligence Industry ScienceTechnology Co,. Ltd. Four-strands continuous billet casting

Billet Specification

150 x 150 mm, Length 6 m

Induction Furnance

25 MT/Heat

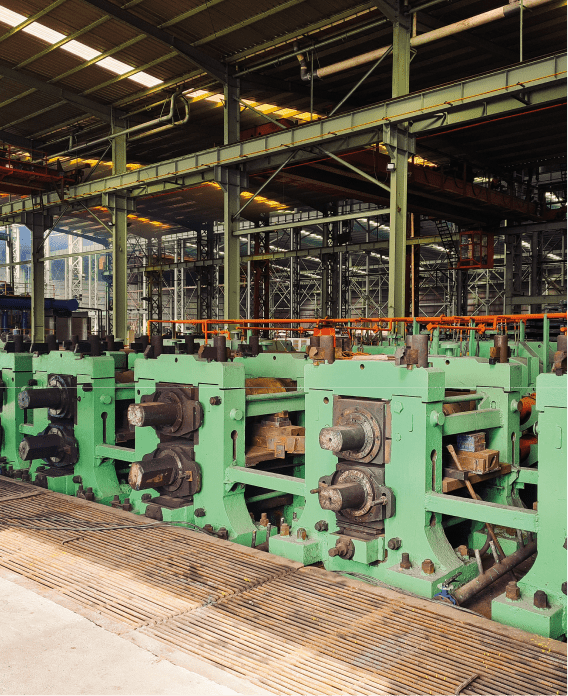

ROLLING MILLS

ROLLING MILLS — A

Deformed Bar Sizes

8 — 13 mm

Plain Bar Sizes

8 — 13 mm

Reheating Furnance

Walking Beam,Top and Bottom Fired, 50MT/HR

ROLLING MILLS — B

Deformed Bar Sizes

13 — 32 mm

Plain Bar Sizes

13 — 32 mm